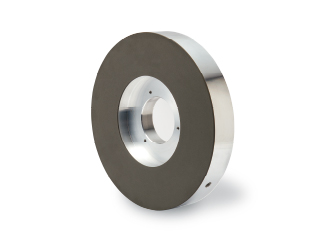

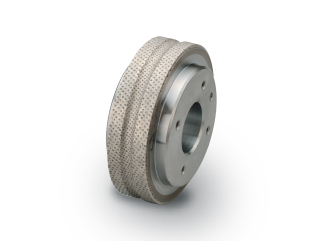

Vitrified CBN Wheel

Tough Premium Vi

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

Vitrified CBN wheels having truing intervals as long as three times those of existing series products make it possible to reduce the tool cost, improve the grinding accuracy and reduce the grinding time. Stiff CBN grains extending the service life of the cutting edge, strong vitrified bonding agent having a good affinity with grains, and innovational distribution technology serve as key technologies in the improvement of the cutting performance as well as the service life.

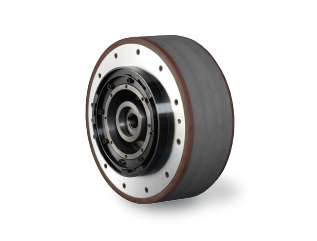

e wheel

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

While conentional wheels play the main role in the regular surface speed zone, we propose e-Wheel as a CBN wheel for the regular surface speed zone that can provide major advantages in this zone. e-Wheel has lots of advantages such as a stable grinding accuracy, reduced running cost and reduced waste when compared with normal wheels.

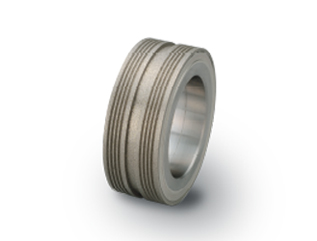

Tough Vi-F series

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

Vitrified CBN wheels having improved cutting performance and truing intervals as long as twice those of existing series products in the high concentration zones make it possible to reduce the tool cost and grinding time. Products in this series are used for cam grinding (rough grinding), crank shaft grinding and so on.

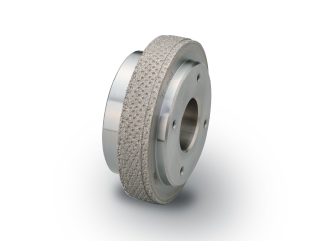

VB series

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

General-purpose series that can meet various requirements ranging from low to high concentration zones.

Resin Wheel

- Machine Parts

Resin Wheel for Double Disc Grinding of Sintered Unhardened Steel GaiaR i BG7

Grinding performance is favorable for sintered unhardened alloy materials, unhardened and quench-hardened ferrous materials, unhardened cast iron, and the like, and cutting performance is also excellent compared to our conventional products (with grinding resistance reduced by 15% to 30%), and the grinding ratio is around 1.2 to 2.4 times higher. This can be used with all types of materials.

- Machine Parts

Resin Wheel for Internal Grinding (Rough grinding) Teramate

This resin wheel boasts excellent cutting performance. Establishing a high Young's modulus for the bond makes it possible to maintain good abrasive-grain protrusion with little grain sinking during grinding, enabling high-efficiency grinding.

- Machine Parts

Resin CBN Wheel for Through-feed Centerless Grinding GaiaR i BG6

The abrasive grains were selected to maintain blade sharpness for long times. The adhesion performance of the grains and binder has been improved to reduce grain loss. This can be used to enhance tool-cost performance thanks to reduced wheel wear with quench-hardened ferrous materials.

GaiaRi

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

CBN grains having superior cutting performance and improved grain bonding force are key technologies in the improvement of cutting performance and service life of this resin wheel. The service life is extended to twice and the flatness is improved by 30% in double head surface grinding when compared with those of earlier models. The service life is beyond 2.5 times that of existing models in through-feed center-less grinding.

Ulteel

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

A resin-based bonding material is used to increase resilience, working softly on the workpiece. Because the cutting performance is superior while generation of chipping and cracks is fewer, the product is used for applications such as the grinding of hard and fragile materials and tool grinding where the sharp cutting edge is needed. It is also used for the grinding of cemented carbide and ceramics.

Ulteel Ⅱ

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

Truing is easy and the dressing process on the machine is almost unnecessary. The heat conductivity of the bond is good and thermal deterioration of the bond is less with this wheel.

Metal Wheel

Ultra-mate

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

Metal bond wheels offer excellent heat resistance and thermal conductivity and can serve for many years to come because of the metal used as a bonding agent. However, they are inferior as to the ease of truing and dressing and sharpness compared to resin bond wheels. Ultra-mate is a metal bond wheel using a special lubricant to cover this disadvantage.

Electroplated wheel

Dressers

- Machine Parts

- Automotive and Transportation Equipment

Diamond Dresser for Gear Grinding UP Dresser Premium

Optimized and equalized high precision and amount of diamond lapping as well as improved diamond holding force for the plating achieve long service life and favorable dressing performance. You can select either of two types: one emphasizing dressing cutting performance and one emphasizing useful life. It can also optionally be used for dresser tip reinforcement.

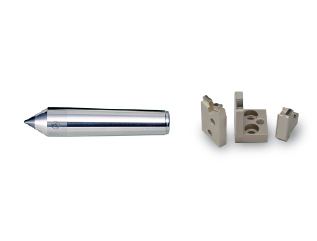

Diamond truer Tough Premium Ti

- Machine Parts

- Automotive and Transportation Equipment

The diamond holding force improved with a strong bonding agent serves as a key technology in the improvement of the service life twice that of the existing metal bond type diamond truer. Use Tough Premium Ti diamond truer with Tough Premium Vi Series vitrified CBN wheels to extend the wheel performance to the largest.

Infiltrated method

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

A diamond is fixed using a powder metallurgy method. Compared with other processed rotary dressers, infiltrated method rotary dressers are sturdy and correctable and reusable even if they deteriorate in regards to accuracy or are deformed.

Reverse plated method-SC type

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

Grains of diamond are fixed by an electroplating method. Reverse plated method rotary dressers suffer little thermal strain because the manufacturing of reverse plated method dressers does not involve high-temperature processes. Reverse plated method rotary dressers are suitable for fine, complicated shapes and shapes requiring high accuracy.

Reverse plated method-DD type

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

The distribution density of rotary dressers is reduced by dimples scattered on the surface. The edge shape of the diamond is sharp to minimize required lapping.

Reverse plated method-HS type

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

Diamond is set by hand, so the distribution density can be adjusted. Compared with the infiltrated method, point of diamond can be kept sharper during finishing process because of its smaller amount of lapping. This makes excellent cutting ability of grinding wheel after its being dressed.

Various stationary type dresser

- Machine Parts

- Automotive and Transportation Equipment

Dresser with one or more diamonds set on a shank. Each dresser, fixed to the machine, trues and dresses the face of a rotating grinding wheel while holding it against the dresser.

PCD & PCBN

PCD & PCBN cutting tools

- Machine Parts

- Automotive and Transportation Equipment

PCD combines the wear resistance of a diamond and the strength and toughness of tungsten carbide. PCD demonstrates stable performance for a long time because it is free of fluctuations attributable to crystal orientation, which are observed with natural diamonds. However, it is inferior in surface roughness to natural diamonds. PCBN formed by sintered ultra-fine particles of CBN is used for hardened steel, chilled cast iron, heat-resistant alloys, etc. and characterized by a high cutting speed and long tool life.

Diamond wear resistant products

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

PCD is second in hardness only to natural diamonds and have a wear resistance about more than 100 times that of cemented carbide. If these wear resistant products with extremely low wear losses are specifically used for parts that affect product accuracy, products will maintain stable quality for longer. They are adopted for a wide variety of parts, including precision machine parts and measurement reference sections. Diamond centers and workpiece rest shoes are representative of such products.

Devices and equipment

Tool grinding machines(DPCG-4)

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

High-precision, High-rigidity grinders enhance efficiency of polycrystalline diamond tool grinding.

Chamfering machines

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

All that is required is to turn the tip while applying light finger pressure to it along the jig installed.

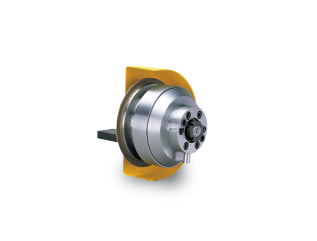

Compact truing devices

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

High-efficiency truing achieved by the motor-driven mechanism(With inverter).

General-purpose truing devices

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

Easy truing of CBN wheels on multi-purpose cylindrical grinders.

Brake controlled truing device

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

Power supply unit unnecessry. Truing and dressing done at the same time.

Others

Diamond powder / Diamond paste

- Machine Parts