Continuing to Further Refine Globally Top-class Quality

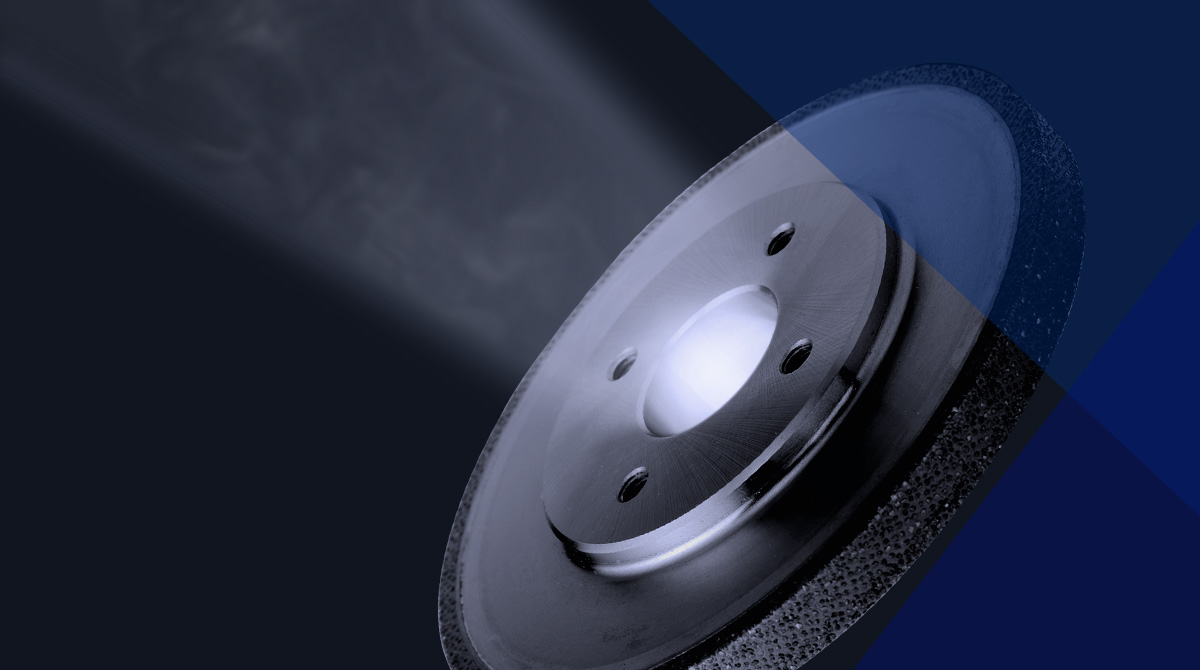

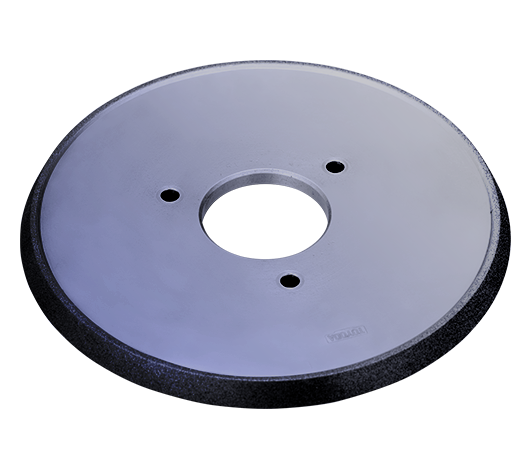

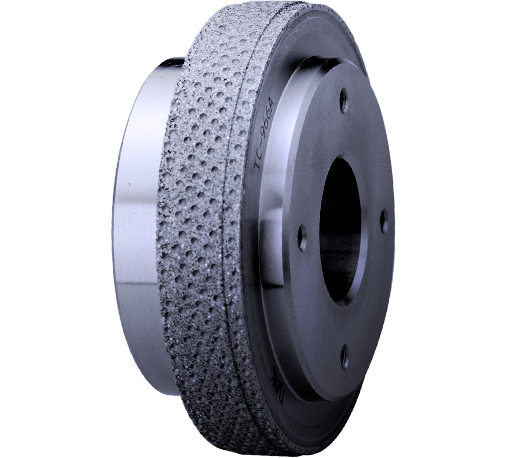

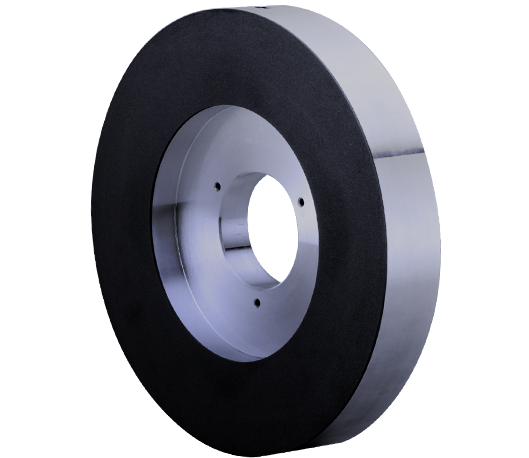

Our main products – CBN vitrified wheels – offer both high cutting performance and long useful life, and are used by Japanese carmakers as well as major overseas manufacturers. Our products also boast ultra-high precision that is globally top-class and achieve quality so high that many customers tell us that for difficult machining tasks, it has to be grindstones and dressers from JTEKT GRINDING TOOLS CORPORATION. By continuing to refine this world-class quality that we take pride in, we will make ultra-abrasive tool products from JTEKT GRINDING TOOLS, including our resin wheels, metal wheels, and other wheel products, lead the way in product-making around the world.

Taking Up the Challenges of Semiconductors, Motors, and Other New Products

In the automotive industry, the advent of plug-in hybrid vehicles (PHVs) and electric vehicles (EVs) as well as self-driving cars, connected cars, and other such technology puts us on the cusp of an era of once-in-a-century sweeping change. In IT-related areas, the spread of artificial intelligence, "industry 4.0" with its use of the Internet of things (IoT) and big data in manufacturing operations, and other such developments make for a pressing wave of industrial revolution. By leveraging the expertise we have cultivated in such areas as automobiles, aircraft, and machine tools, JTEKT GRINDING TOOLS is boldly tackling the challenges of the completely new products of semiconductors and motors. All of this is to meet your needs of every kind. JTEKT GRINDING TOOLS will continue to evolve.

Drafting a Growth Strategy through Organizational Reform

JTEKT GRINDING TOOLS is conducting reforms in organization and in awareness oriented toward achieving a strategy for growth and its implementation. What is more, we are simultaneously pressing ahead with such measures as strengthening our human-resource recruitment of new college graduates and others, boosting our production capabilities through automation and upgrades to our equipment and facilities at our plants in Japan and Vietnam, and expanding sales to overseas markets, and these are steadily beginning to yield positive results. On the ground, instead of being satisfied with attainable kaizen improvements, we are achieving breakthroughs for targets that transcend what has previously been the conventional wisdom, such as "reducing lead times by 50%," thereby elevating our global competitiveness.