Resin Wheel Metal Wheel

- Aerospace / Electronics and Semiconductors

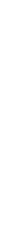

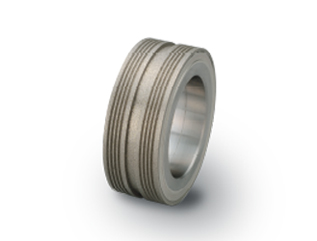

Resin Wheel for Ceramics Grinding Teramate Premium

This resin wheel offers high-precision, high-efficiency machining. Grain size and the chip pocket have been optimized, making this useful for high-precision grinding, and establishing a high Young's modulus for the bond makes it possible to maintain good abrasive-grain protrusion with little grain sinking during grinding, thereby achieving high-efficiency grinding.

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

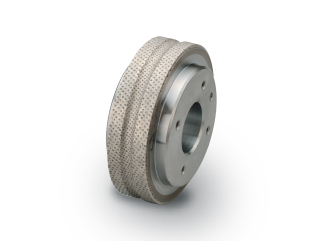

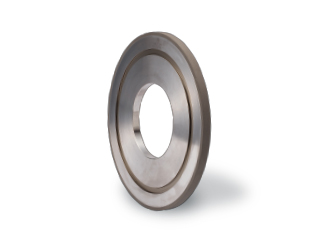

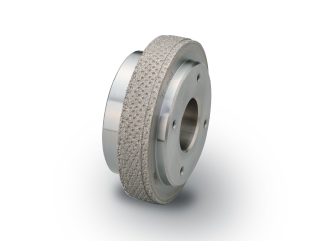

Metal Wheel for Grinding Difficult-to-cut Materials Teramate MT2

Metal is used for the binder. Optimizing the abrasive-grain type, reduction of low friction due to bond microfracture, and a suitable amount of wear make for superior grinding performance in high-efficiency regions compared to the Teramate (resin bond). This is applicable for grinding Inconel.

Vitrified diamond Wheel

- Aerospace / Electronics and Semiconductors

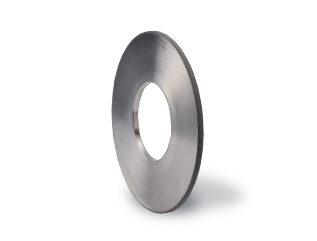

For wafer grindingVitrified Wheel nanoVi

Innovated manufacturing method provides uniform distribution with The size of φ0.5um grain. This technology brings a Ra0.8nm finish for 6" SiC wafer.

Dressers

Infiltrated method

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

A diamond is fixed using a powder metallurgy method. Compared with other processed rotary dressers, infiltrated method rotary dressers are sturdy and correctable and reusable even if they deteriorate in regards to accuracy or are deformed.

Reverse plated method-SC type

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

Grains of diamond are fixed by an electroplating method. Reverse plated method rotary dressers suffer little thermal strain because the manufacturing of reverse plated method dressers does not involve high-temperature processes. Reverse plated method rotary dressers are suitable for fine, complicated shapes and shapes requiring high accuracy.

Reverse plated method-DD type

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

The distribution density of rotary dressers is reduced by dimples scattered on the surface. The edge shape of the diamond is sharp to minimize required lapping.

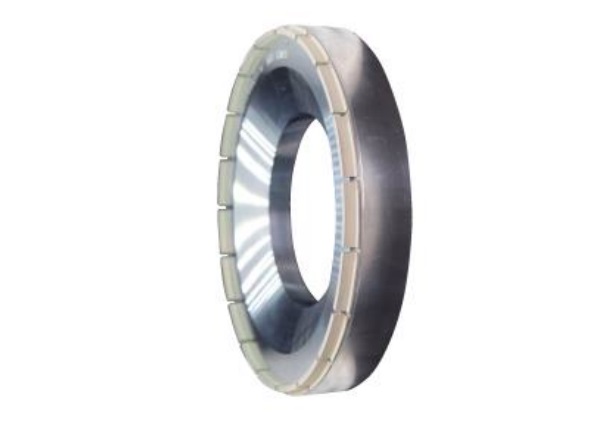

Reverse plated method-HS type

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

- Aerospace / Electronics and Semiconductors

Diamond is set by hand, so the distribution density can be adjusted. Compared with the infiltrated method, point of diamond can be kept sharper during finishing process because of its smaller amount of lapping. This makes excellent cutting ability of grinding wheel after its being dressed.