PCD & PCBN

PCD & PCBN cutting tools

- Machine Parts

- Automotive and Transportation Equipment

PCD combines the wear resistance of a diamond and the strength and toughness of tungsten carbide. PCD demonstrates stable performance for a long time because it is free of fluctuations attributable to crystal orientation, which are observed with natural diamonds. However, it is inferior in surface roughness to natural diamonds. PCBN formed by sintered ultra-fine particles of CBN is used for hardened steel, chilled cast iron, heat-resistant alloys, etc. and characterized by a high cutting speed and long tool life.

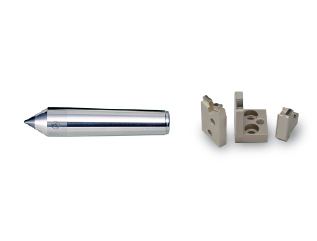

Diamond wear resistant products

- Tools and Dies

- Machine Parts

- Automotive and Transportation Equipment

PCD is second in hardness only to natural diamonds and have a wear resistance about more than 100 times that of cemented carbide. If these wear resistant products with extremely low wear losses are specifically used for parts that affect product accuracy, products will maintain stable quality for longer. They are adopted for a wide variety of parts, including precision machine parts and measurement reference sections. Diamond centers and workpiece rest shoes are representative of such products.